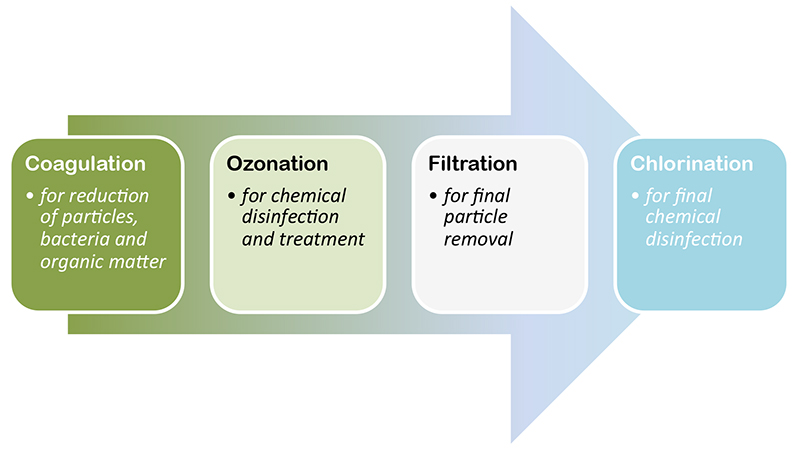

Four primary processes are used at the LFWTP to treat water for pathogenic microorganisms and chemical contaminants:

- Coagulation/Sedimentation,

- Ozonation,

- Filtration, and

- Chlorination

The treatment process flows continuously from beginning (raw source water) to end (finished drinking water, pumped to our customers), 24 hours a day, 7 days a week, under normal conditions. However, the process is monitored electronically at many points along the way, and stops whenever conditions in any of the treatment steps deviate from optimal ranges. The process is also controlled under State and Federal regulations designed to protect the health and safety of our customers.

Coagulation

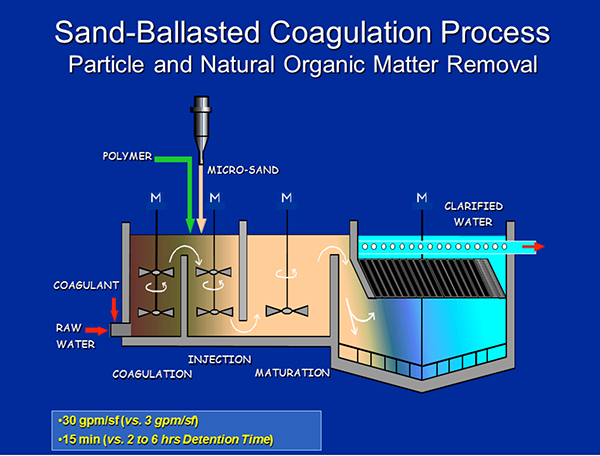

PVWC employs sand-ballasted Actiflo® coagulation, a compact, high flow-rate water clarification process. The process begins when a coagulant (ferric sulfate) is added to the raw water flowing into the coagulation chambers. Coagulation polymer and microsand are then added to the flowing water. The mixture is given time to “mature” and then it flows into specially designed clarification tanks. The outflow from these tanks is water from which much of the particles, bacteria and organic matter have been removed. This advanced coagulation process can produce up to 30 gallons of clarified water per minute per square foot of footprint, compared to a typical production rate of only 3 gallons by the old process it replaced. Furthermore, typical detention time in the process is only 15 minutes from injection to outflow, compared to 2 to 6 hours settling time by the conventional process.

Ozonation

Ozone gas is a highly energetic form of oxygen, the same oxygen present in the Earth’s atmosphere. Ozone is created when oxygen passes through a strong electric field (similar to a lightning flash in the sky). PVWC maintains three advanced on-site ozone generators to create as much ozone as we need for water treatment.

Ozone gas is ideal for drinking water treatment, because it is highly effective at inactivating pathogens (viruses and bacteria) and cleaning up taste and odor components from the water, while leaving behind no residue of its own. By the time the treated water leaves our treatment plant, all its ozone has dissipated.

Clarified water leaving the coagulation/settling process flows to ozone chambers where ozone gas is bubbled through it. The concentration of ozone added to the water is carefully controlled to ensure optimum disinfection and virus inactivation.

Filtration and Chlorination

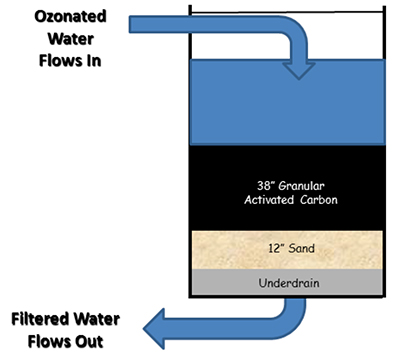

After the clarified water has been treated with ozone gas, it is passed slowly through a bed of Granular Activated Carbon over a base of fine sand. This process polishes the water by removing small particles left over from coagulation and provides additional removal of organic matter not previously removed.

Water leaving the filters is stored in special chambers called Clearwells. The last Clearwell is dosed with liquid sodium hypochlorite to a level of 1.5 – 2.0 parts per million final residual chlorine. This last dose of chlorine is intended to remain in the water as it travels throughout the water mains serving our customers’ cities and neighborhoods. By keeping a small amount of chlorine in the final, finished water, the pipes and water remain protected against intrusions of pathogenic bacteria, keeping the water safe for everyone to drink.

For a majority of PVWC’s customers, finished water from the Little Falls WTP is blended with finished water obtained from the North Jersey District Water Supply Commission’s (NJDWSC) Wanaque WTP. The finished water is then pumped through underground pipes throughout Paterson, Clifton, Passaic, Prospect Park, Lodi, North Arlington and a section of Woodland Park. PVWC also supplies drinking water wholesale to nearly two dozen other municipalities in Passaic, Bergen, Essex, Hudson and Morris counties. Emergency interconnections with other water purveyors exist throughout the distribution system.

Finished Water Reservoirs

Some of the finished drinking water leaving our high-technology Little Falls WTP is deposited in open, man-made reservoirs located in Paterson and Woodland Park. There it remains as a reserve for daily periods of high water demand, similar to water tanks seen in many other towns. Because this open water is exposed to the elements of weather, animals, and plant life, chlorine disinfectant is re-added to the water as it leaves the reservoirs on its way to our customers. This re-chlorination is likely to protect the public against most of the pathogens expected to be added to the drinking water by exposure to nature in our reservoirs.

These open reservoirs are the main reason PVWC cannot better control the corrosivity of our water on lead plumbing. The chemical agents necessary for such control cannot be used in a system with open reservoirs. PVWC is gradually implementing measures designed to improve this situation without adversely affecting the quality of drinking water in our reservoirs. You can read more about this in our Lead Information section.

High Crest Lake Customers

PVWC customers in the High Crest Lake water system receive water that originates in the Kakeout Reservoir in Kinnelon, NJ. The Butler water treatment plant provides this water to PVWC at our High Crest pump station, where we re-chlorinate the water to ensure adequate disinfection and distribute it to our customers.

Post Brook Customers

PVWC customers in the Post Brook water system receive water that originates in underground wells near Nosenzo Pond. PVWC chlorinates this well water at the Nosenzo Pond pump station to ensure adequate disinfection, and we also add a small amount of sequestering agent to keep dissolved minerals from staining our customers’ fixtures and laundry water.

Contact Us

Office Hours:

Monday-Friday

7:30 a.m. – 6:00 p.m.

Main Office:

Passaic Valley Water Commission

1525 Main Avenue

Clifton, NJ 07011

Telephone: 973-340-4300

Fax: 973-340-5598

Emergency:

By calling Customer Service 973-340-4300 at any time, day or night, Passaic Valley Water Commission will respond to water emergency situations for you.